Close cooperation with leading laboratories, technology partners and areas of applied research enable us to develop a whole new generation of testing equipment. We use the latest components, specially developed materials and consistently advanced technologies. ROHMANN supplies the most modern and powerful testing equipment and systems currently available on the market.

We will be happy to answer your individual questions. Simply contact us and use our search or the inquiry form.

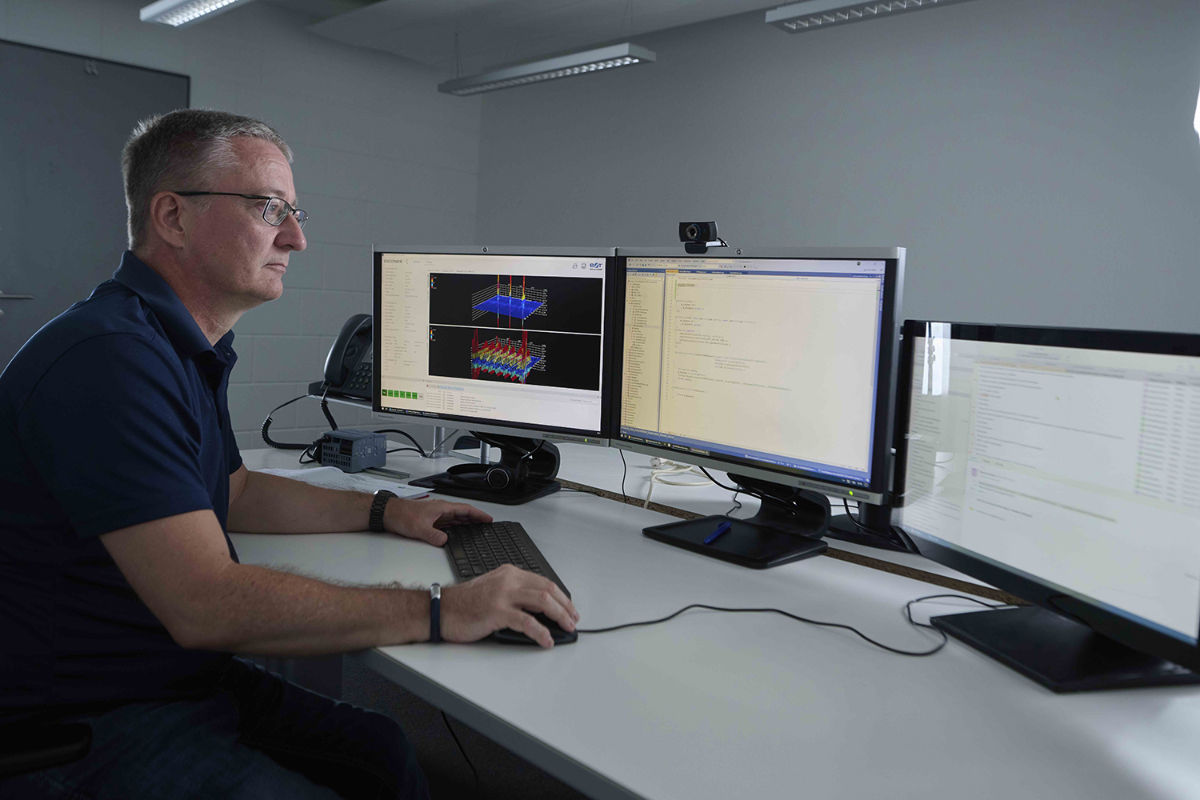

Siemens Power Generation Services offers service solutions for gas or steam turbines, generators or wind turbines worldwide to increase the efficiency, reliability and operational flexibility of plants. For its global maintenance services, the company relies, among other things, on the ROHMANN ELOTEST M3 manual testing device

Dillinger manufactures technologically outstanding and versatile heavy plate at its traditional Saar location. This is backed up by references from all over the world in a wide variety of application areas. Especially for pipeline applications, the HST test method developed by ROHMANN supports the precision and consistently high quality of Dillinger products.

Eisenwerk Brühl GmbH specializes in the development and series production of cast engine blocks for the automotive industry. The company is one of the main suppliers of cast iron ZKG for passenger cars. To safeguard the production process, i.e. to detect material defects, hand-held and line inspection devices from ROHMANN are used.

Lufthansa Technik offers a full range of aircraft technical services, including maintenance, overhaul and testing of engines and landing gears. For example, in addition to the robot-based ELOSCAN test systems, Lufthansa Technik AG also uses sensors and portable test equipment from ROHMANN at several locations in Germany.

A subsidiary of the Etihad Aviation Group, the company provides scheduled, light and heavy maintenance services. The largest commercial aircraft maintenance, repair and operations service provider in the Middle East uses both the ELOTEST M2 handheld tester and the ELOWHEEL 1000 (RPT16) rim inspection system to inspect their aircraft.

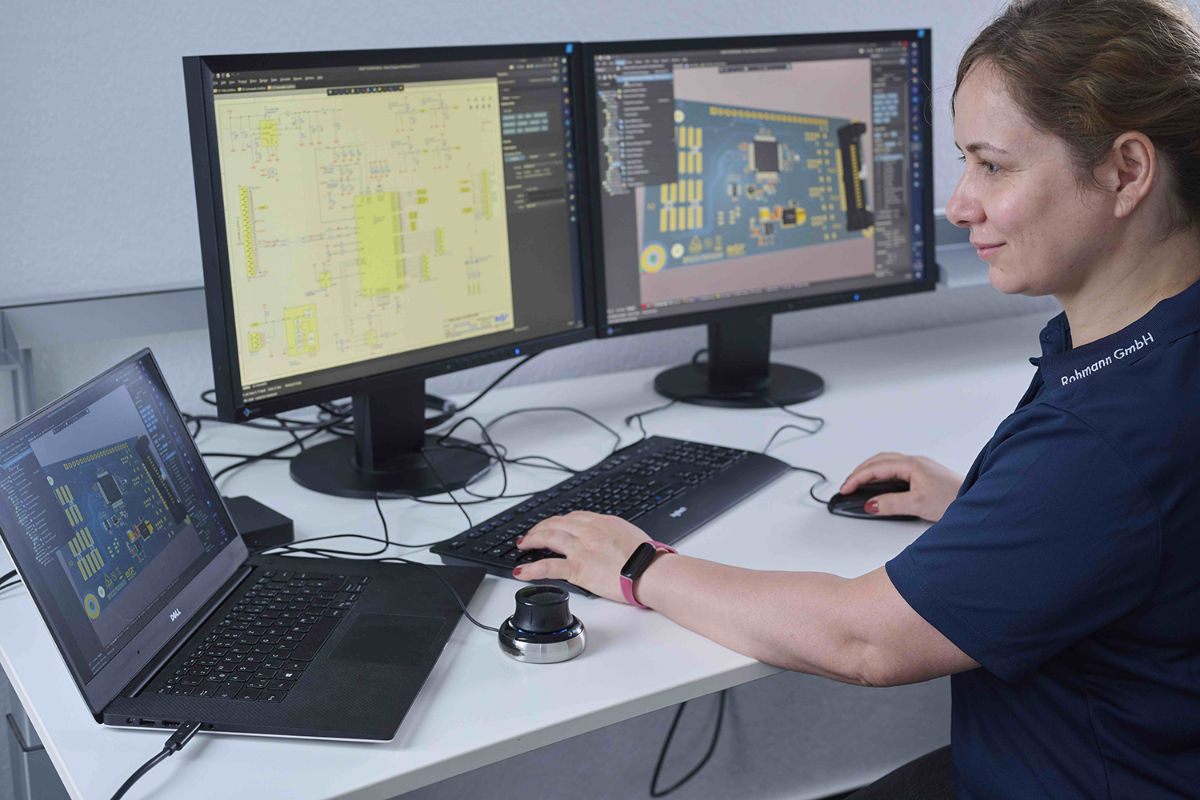

NKT is an established and globally active supplier of turnkey cable systems for direct and alternating current and provides innovative cable solutions for worldwide energy transport. For the quality assurance of its own products, NKT uses the ELOTEST IS500 line tester from ROHMANN.

As an aviation manufacturing and maintenance company with a long tradition, Zeppelin offers professional QM services for the global aviation industry, the automotive industry and for mechanical and plant engineering. For the aerospace sector, Zeppelin carries out ZFP training using hand-held Elotest M3 test equipment, test probes and calibration standards from ROHMANN.