Press reports

23/09/2020

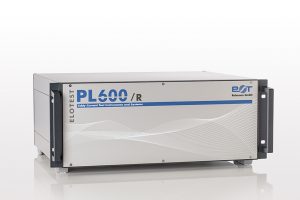

ELOTEST PL600 R + RC

ADDITION TO THE “ELOTEST PL600” FAMILY OF INSTRUMENTS FOR NON-DESTRUCTIVE MATERIALS TESTING THE LATEST GENERATION OF EDDY CURRENT TESTERS FROM ROHMANN GMBH.

The “ELOTEST PL600” is the latest development from Rohmann. The family-owned company from Frankenthal in the Palatinate region of Germany has been developing and selling eddy current testing equipment and accessories for non-destructive materials testing for 43 years. With the ELOTEST PL600, a digital tester of the latest generation, all types of eddy current testing can be performed. It is suitable for crack and heat treatment testing as well as for material mix-up and grinding burn testing.

Article download25/09/2020

Rolling bearing

COMBINED CRACK AND GRINDING BURN INSPECTION WITH SINGLE SENSOR AND ARRAY SENSOR ON BEARING RINGS AND ROLLING HEADS

NON-CONTACT, FAST, HIGH-RESOLUTION AND EFFICIENT.

In addition to a wide variety of tasks from industry, a current topic is crack and grinding burn testing on bearing rings and rolling elements. This customer requirement can be solved semi-automatically and also fully automatically. Depending on the test task, single probes or array probes can be used.

Article download

EloWheel

ELOWHEEL” RIM TESTING SYSTEM FROM ROHMANN FOR NON-DESTRUCTIVE MATERIAL TESTING

EDDY CURRENT TESTING SYSTEMS IN USE WORLDWIDE IN THE MRO SECTOR.

Eddy current test equipment and systems from Rohmann are used in a wide variety of industries around the world. While test equipment can be used across industries, test systems/plants are usually designed for the inspection of a specific test piece. For nearly four decades, Rohmann’s EloWheel, developed for aircraft wheel testing, has been found in wheel stores of well-known companies in the MRO sector all over the world. A success story that continues to this day and that Rohmann would like to continue with the current version of the testing system. High-quality components, a stable steel construction and the latest testing device from Rohmann – the ELOTEST PL600 – are used. Very great importance was also attached to the safety of the user.

Article downloadTrolley WPG D340

ON THE WAY ON THE WORLDWIDE RAIL NETWORK THE ROHMANN TROLLEY IS SUITABLE FOR DIFFERENT TRACK WIDTHS.

The WPG D340 trolley brings eddy current to the rails, according to Rohmann GmbH from Frankenthal. The specialist for non-destructive materials testing now supplies its successful product all over the world. Whereas the trolley was previously manufactured individually for different track widths, the current design allows universal use for track widths from 1400 to 1700 mm. This should please not only the railroad companies but also their service partners responsible for track maintenance. This means that a trolley produced for the European rail network can now also be used outside Europe, which of course saves costs.

Article download