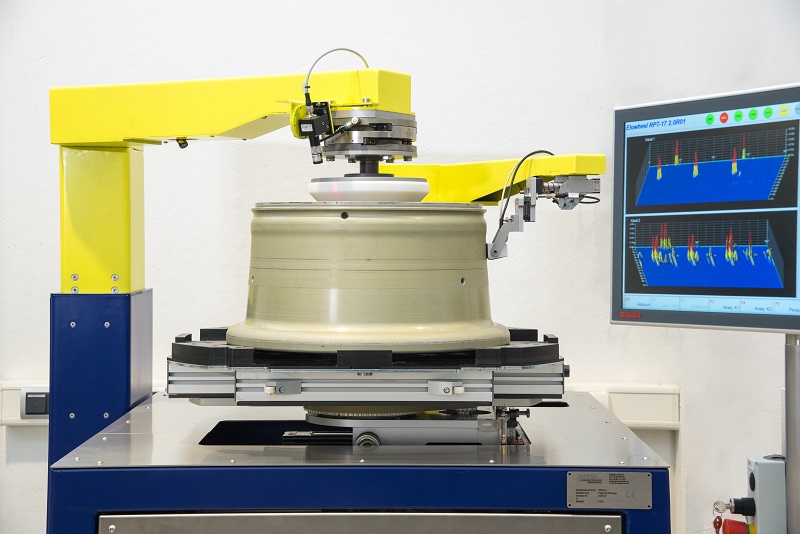

ROHMANN Eddy Current Test Instruments and Systems

Since 1977 we have been developing, producing and distributing eddy current testing devices and systems, which are now used worldwide in crack, heat treatment, material confusion and grinding burn testing. Testing solutions for every requirement and every demand. Made in Germany.