Description

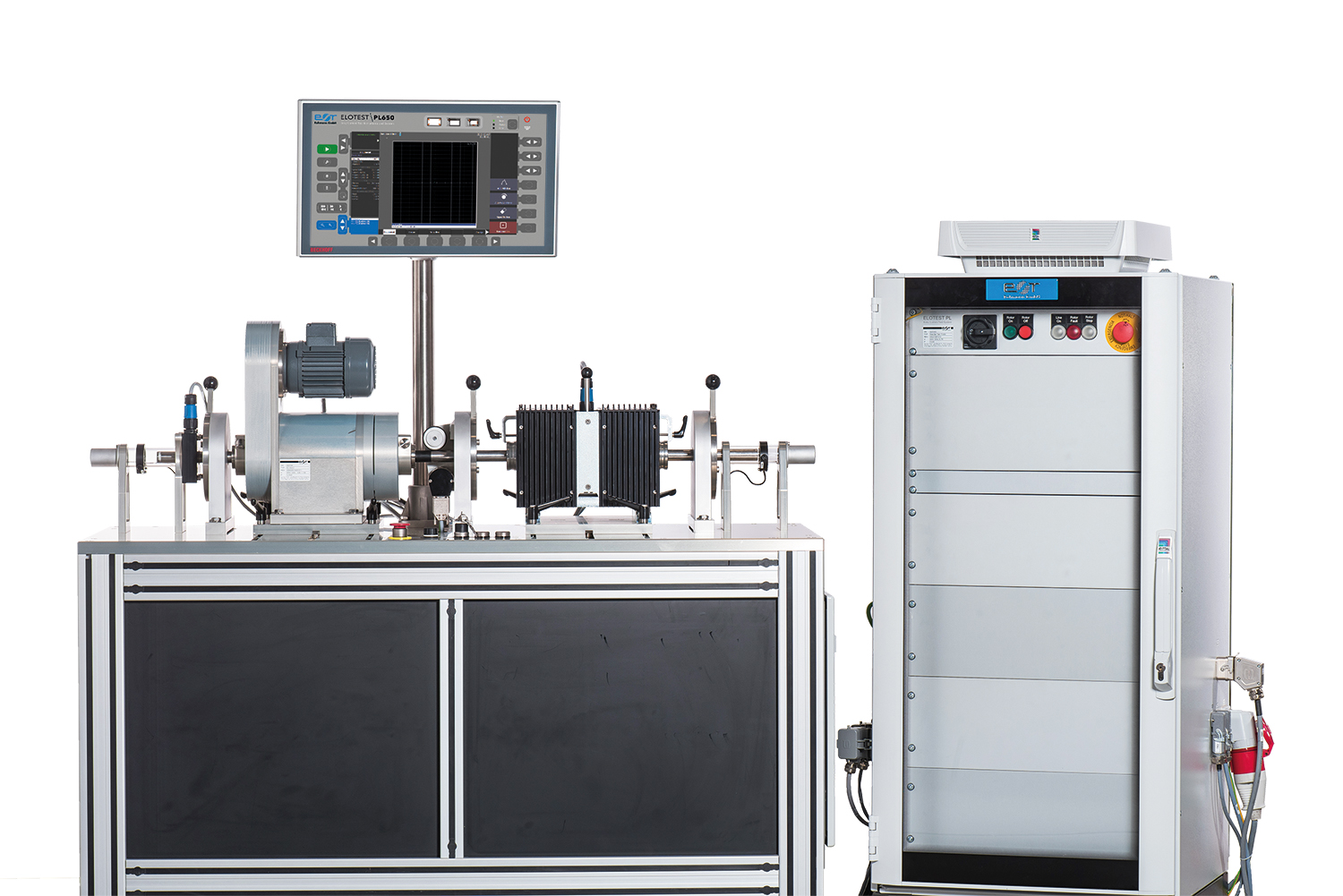

Eddy current testing of long products and semi finished products with the ELOTEST \ PL650 test instrument, ELO \ LINE software and rotors. When long products are inspected for circumferential and spot-like defects, they are usually guided through encircling differential test coils of the ULAD type.

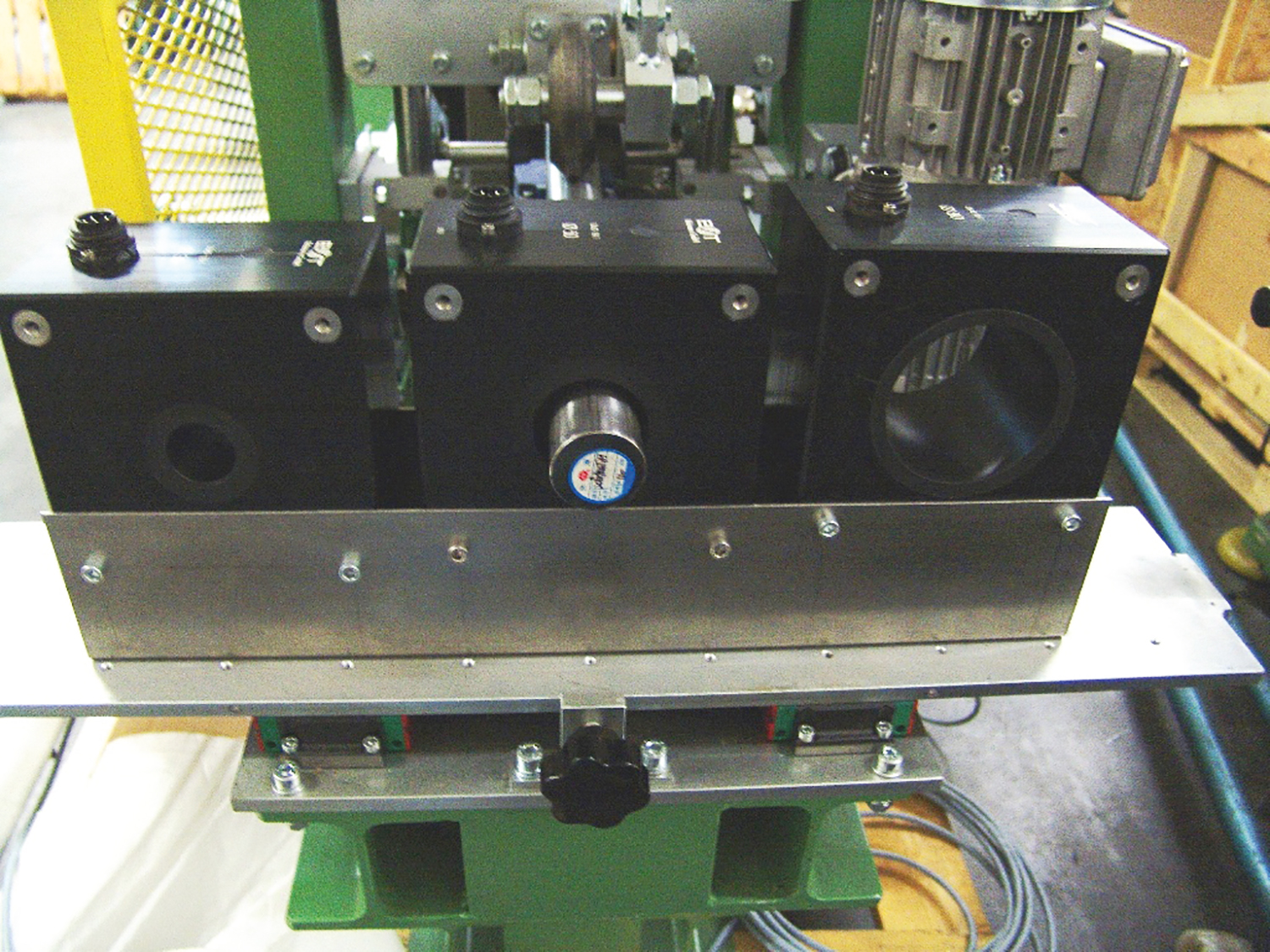

The absolute coil also provided makes it possible to detect longitudinal defects such as slot welds in welded pipes or tubes. Segment coils of type LDA are usually used for weld seam testing. These can be customized for special geometries.

The sensors are selected according to the requirements to be met by the inspection. Differential sensors with distance compensation are used for many tasks. The usual effective width is between 1 and 15 mm. Together with a suitable rotation speed of the coils, a very high throughput can be achieved in continuous operation.